The Gasoline Particulate Filter (GPF), a ceramic filter installed in the gasoline engine emission system, reduces the particulate quality and quantity by 80-90%. Even higher, is effectively reduces the number of PM, PN technical solutions.

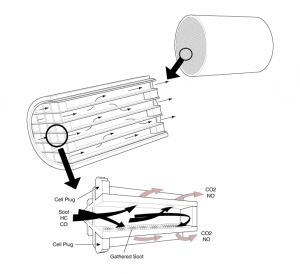

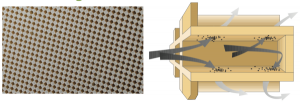

GPF filtration mechanism is the same as DPF of diesel engines. Exhaust gas passes through the porous Wall surface at a certain velocity, which is called “wall flow”. The wall flow particle catcher consists of honeycomb ceramic with a certain pore density. By blocking the honeycomb porous ceramic filter alternately, the exhaust flow is forced to pass through the pore wall, and the particles are captured and filtered by diffusion, interception, gravity, and inertia respectively.

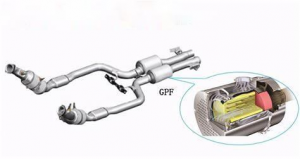

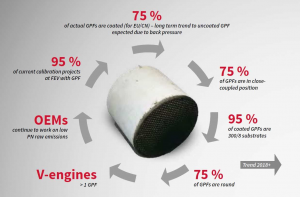

The arrangement of GPF on the exhaust pipe of gasoline engines mainly consists of one form, one integrated with TWC and installed together, which is close to the exhaust pipe, namely the Closed-coupled arrangement. Another kind is directly installed in the downstream position of TWC, namely, an Under-floor, abusive, and another kind is coated on the base material of GPF to form a “quadruple catalyst”.

GPF is divided into white carrier GPF and coated GPF according to whether it contains coating. White carrier GPF only has the function of particulate trapping, coated GPF inner wall coating coated with precious metal and cerium oxide, etc. When the exhaust passes through the wall between the channels, oxygen is adsorbed or released by cerium oxide, and gaseous emissions with the help of precious metal catalysts react to produce carbon dioxide, nitrogen, and

water, which is more comprehensive in reducing pollution emission

Regarding whether GPF catalytic converter is coated, we have the following suggestions for an optional reference 1 First, Suppose the customer does not have a strong regeneration function of the GPF, uses it under suitable conditions, and Considers pursuing high-cost performance, We suggest uncoated GPF may be more suitable for you.

2 But If the condition is like this. We will recommend the coated GPF more. (1) The Engine’s raw emissions are poor causing the emission of particulate matter to be high. (2)The emission temperature is low. (3) More importantly, if the customer has a strong regeneration function of the GPF, the regeneration function of the coated GPF to capture particulate matter will prolong the 50% regeneration period of the GPF itself and will improve The collection efficiency of GPF is 10%-30%

After the particle filter is used for a long time, soot particles accumulate on the surface of the filter pores to form a PM layer, and its storage volume will gradually decrease. The formation of the DM layer can help improve the filtration efficiency, but there will be a throttling effect in the exhaust pipe, and the flow of the exhaust gas will become larger, resulting in an increase in fuel consumption and a decrease in engine output power. At this time, the GPF needs to be replaced or regenerated.

Hope it will be helpful for your side and please don’t hesitate to contact me if you need further information

Post time: Jan-06-2023